HOW TO STORE CEMENT ON SITE?

STORING OF

CEMENT ON SITE – GUIDELINES

CEMENT ON SITE – GUIDELINES

·

Cement

should be store in a building which is dry, leak proof and moisture proof as far

as possible.

Cement

should be store in a building which is dry, leak proof and moisture proof as far

as possible.

·

The

number of windows should be minimum in the storage cement building.

The

number of windows should be minimum in the storage cement building.

·

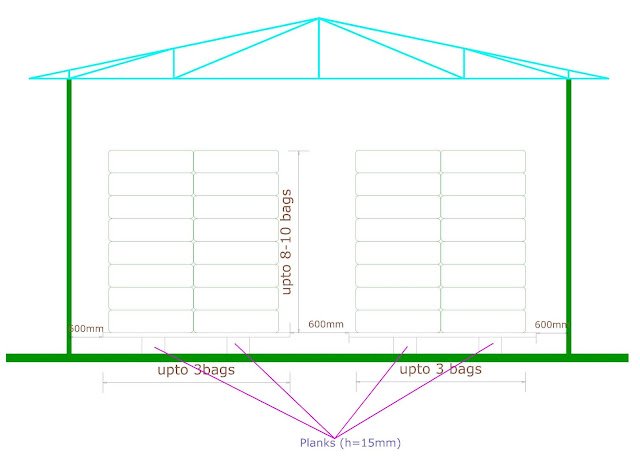

If

the floor is damp than stack the cement bags off the floor on wooden planks in

such a way, so that it is about 150 mm – 200 mm above the damp floor.

If

the floor is damp than stack the cement bags off the floor on wooden planks in

such a way, so that it is about 150 mm – 200 mm above the damp floor.

·

During

storing cement we have to maintain a space of 300 mm all around between the

exterior walls and the stacks.

During

storing cement we have to maintain a space of 300 mm all around between the

exterior walls and the stacks.

·

Cement

bags should be stack close to each other to reduce circulation of air between

bags.

Cement

bags should be stack close to each other to reduce circulation of air between

bags.

·

The

height of cement bags stack should not be more than 10 bags to prevent the

possibility of lumping under pressure.

The

height of cement bags stack should not be more than 10 bags to prevent the

possibility of lumping under pressure.

·

The

width of the cement bags stack should not be more than four bags length or 3

meters.

The

width of the cement bags stack should not be more than four bags length or 3

meters.

·

While

stacking cement bags more than 8 bags high, the cement bags should be arranged

alternately length-wise and cross-wise, so as to tie the stacks together and

minimize the danger of toppling over.

While

stacking cement bags more than 8 bags high, the cement bags should be arranged

alternately length-wise and cross-wise, so as to tie the stacks together and

minimize the danger of toppling over.

·

Stack

the cement bags in such a manner so as to facilitate their removal and use in

the order in which they are received.

Stack

the cement bags in such a manner so as to facilitate their removal and use in

the order in which they are received.

·

Put

label showing date of receipt of cement on each stack of cement bags to know

the age of cement.

Put

label showing date of receipt of cement on each stack of cement bags to know

the age of cement.

·

When

it is required to store cement bas for a long period of time or for during the

monsoon seasons, completely enclose the stack by a water proofing membrane such

as polyethylene.

When

it is required to store cement bas for a long period of time or for during the

monsoon seasons, completely enclose the stack by a water proofing membrane such

as polyethylene.

·

Different

types of cement bags like (OPC, PPC, PHC etc.) must be stacked and stored

separately.

Different

types of cement bags like (OPC, PPC, PHC etc.) must be stacked and stored

separately.

|

| Storage of Cement |

HOW TO STORE

STEEL ON SITE?

Steels should be stored in such a way, so as

to avoid distortion and to prevent deterioration and corrosion. In order to prevent any compromise in the TMT steel

bars for construction, reinforced bars must be handled and stored with

precaution. Proper handling of the TMT bars is essential for its efficiency.

Handling the TMT Re-bars at construction sites involve different operations

namely – Unloading, Hoisting, Stacking, Cutting, Bending, Fabrication, Welding

etc. Since TMT steel rebar plays a crucial role in maintaining the structural

integrity and durability of the building, it is essential all these operations are

properly maintained at the construction site. Steels of different

classes should be stored separately. Follow the guidelines given below while

storing steel on site.

to avoid distortion and to prevent deterioration and corrosion. In order to prevent any compromise in the TMT steel

bars for construction, reinforced bars must be handled and stored with

precaution. Proper handling of the TMT bars is essential for its efficiency.

Handling the TMT Re-bars at construction sites involve different operations

namely – Unloading, Hoisting, Stacking, Cutting, Bending, Fabrication, Welding

etc. Since TMT steel rebar plays a crucial role in maintaining the structural

integrity and durability of the building, it is essential all these operations are

properly maintained at the construction site. Steels of different

classes should be stored separately. Follow the guidelines given below while

storing steel on site.

STORING OF STEEL REINFORCEMENT

·

Whenever the rebars are

ordered, the area where it must be unloaded must be moisture and dust free.

Also at the time of unloading, use timber beds in order to avoid contact with

dirt and water.

Whenever the rebars are

ordered, the area where it must be unloaded must be moisture and dust free.

Also at the time of unloading, use timber beds in order to avoid contact with

dirt and water.

·

Covering the steel

rebars with polythene sheets will protect the reinforced bars from moisture.

Alternatively, a covered shed can be used.

Covering the steel

rebars with polythene sheets will protect the reinforced bars from moisture.

Alternatively, a covered shed can be used.

·

Store

bars of different classes, sizes and lengths separately to facilitate issues in

such sizes and lengths so as to minimize wastage in cutting from standard

lengths.

Store

bars of different classes, sizes and lengths separately to facilitate issues in

such sizes and lengths so as to minimize wastage in cutting from standard

lengths.

·

Optimize the stacking

height for the reinforced bars. The more the stacking height, the more load

bars will have to endure at the lower layers. The excessive load may damage the

Ribs on the surface of the rebar, which in turn reduces tensile strength.

Optimize the stacking

height for the reinforced bars. The more the stacking height, the more load

bars will have to endure at the lower layers. The excessive load may damage the

Ribs on the surface of the rebar, which in turn reduces tensile strength.

·

Paint

the ends of bars of each class in distinct separate colors.

Paint

the ends of bars of each class in distinct separate colors.

·

Coat

steel reinforcement with cement wash before stacking to prevent scaling and

rusting.

Coat

steel reinforcement with cement wash before stacking to prevent scaling and

rusting.

·

If

reinforcement bars have to be stored for a long period, then stack it above

ground level by at least 150 mm.

If

reinforcement bars have to be stored for a long period, then stack it above

ground level by at least 150 mm.

STORING OF

STRUCTURAL STEEL ( I beam, C channel, Angle etc.)

·

Assign separate areas for storing

structural steel of different classes, sizes and lengths.

Assign separate areas for storing

structural steel of different classes, sizes and lengths.

·

Store it above ground level by at least

150 mm upon platforms, skids or any other suitable supports to avoid distortion

of sections.

Store it above ground level by at least

150 mm upon platforms, skids or any other suitable supports to avoid distortion

of sections.

·

In coastal areas or in case of long

storage, apply protective coating of primer to prevent scaling and rusting.

In coastal areas or in case of long

storage, apply protective coating of primer to prevent scaling and rusting.

HOW TO STORE AGGREGATES ON

SITE?

SITE?

STORING OF AGGREGATE ON SITE

·

Whenever the aggregate

and sand are ordered, the area where it must be unloaded must be moisture, mud

and dust free. Also at the time of unloading, use polythene layer on ground in

order to avoid contact with dirt and water.

Whenever the aggregate

and sand are ordered, the area where it must be unloaded must be moisture, mud

and dust free. Also at the time of unloading, use polythene layer on ground in

order to avoid contact with dirt and water.

·

Store

aggregate at site on a hard dry and level patch of ground

Store

aggregate at site on a hard dry and level patch of ground

·

While

unloading aggregate and sand if such a surface is not available then prepare a

platform of planks or old corrugated iron sheets, or a floor of bricks, or a

thin layer of lean concrete so as to prevent aggregate from contamination with

clay, dust, vegetable and other organic matter.

While

unloading aggregate and sand if such a surface is not available then prepare a

platform of planks or old corrugated iron sheets, or a floor of bricks, or a

thin layer of lean concrete so as to prevent aggregate from contamination with

clay, dust, vegetable and other organic matter.

·

While

unload aggregate and sand we have to maintain sufficient distance between

stacks of fine and coarse aggregates to prevent the material from getting

intermixed.

While

unload aggregate and sand we have to maintain sufficient distance between

stacks of fine and coarse aggregates to prevent the material from getting

intermixed.

·

At

a construction site or unloading area, if possible then construct temporary partition

walls to give each type of aggregate its own compartment.

At

a construction site or unloading area, if possible then construct temporary partition

walls to give each type of aggregate its own compartment.

·

Stack

the fine aggregate in such a place where loss due to effect of wind is minimum.

Stack

the fine aggregate in such a place where loss due to effect of wind is minimum.

·

Stacking

of the aggregates should be carried out in regular stacks. The suggested sizes

for stacks are as follows.

Stacking

of the aggregates should be carried out in regular stacks. The suggested sizes

for stacks are as follows.

|

Material

|

Size

of Stack (in m.) To find out quantity |

||

|

Length

|

Breadth

|

Height

|

|

|

Soling

stone |

5

|

2

|

0.5

|

|

5

|

1

|

0.5

|

|

|

Coarse

aggregate |

2

|

2

|

0.5

|

|

5

|

5

|

1

|

|

|

5

|

1

|

0.5

|

|

|

Fine

aggregate |

2

|

2

|

0.5

|

|

5

|

5

|

1

|

|

|

5

|

1

|

0.5

|

|